Strategic sourcing and its benefits

Strategic sourcing is a procurement approach that prioritizes finding the best value in the marketplace by consolidating purchasing power and maintaining long-term supplier relationships. It involves identifying the right suppliers, negotiating contracts, and continuously improving purchasing activities to save costs and improve efficiency.

The process of procuring goods and services is integral to improving performance and efficiency and gaining a competitive edge. With market globalization taking priority and technological advancement coming into play, companies should resort to adopting effective sourcing skills to provide them with an advantage.

Strategic sourcing can help businesses do just that. This article aims to provide a detailed insight into strategic sourcing, the steps involved, its benefits, and how procurement automation (like e-sourcing) can help.

What is strategic sourcing?

Strategic sourcing is a process designed to enhance efficiencies across spend categories. It minimizes supply risks through meticulous supplier selection, providing visibility into pricing and forecasting. It involves identifying spending profiles and leveraging the purchasing power of a company to obtain goods or services from vendors at optimized values to stay in line with business goals.

This type of strategic procurement process is now popular as it aims to transform the way businesses view and engage in supply chain management. It seeks to create better efficiency in the company’s acquisition process, minimize risk in the supply chain process, and enhance visibility in price forecasting for better profitability.

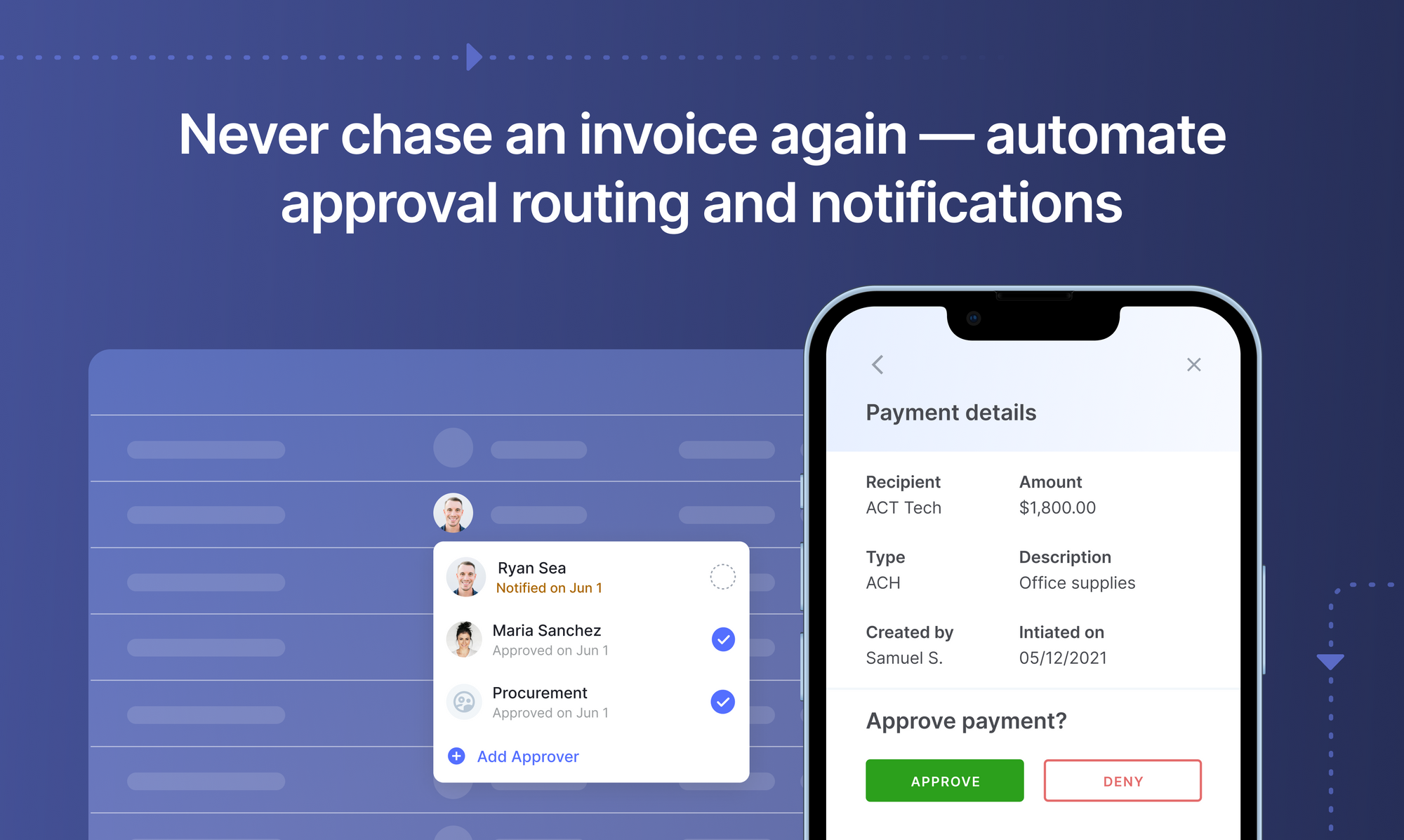

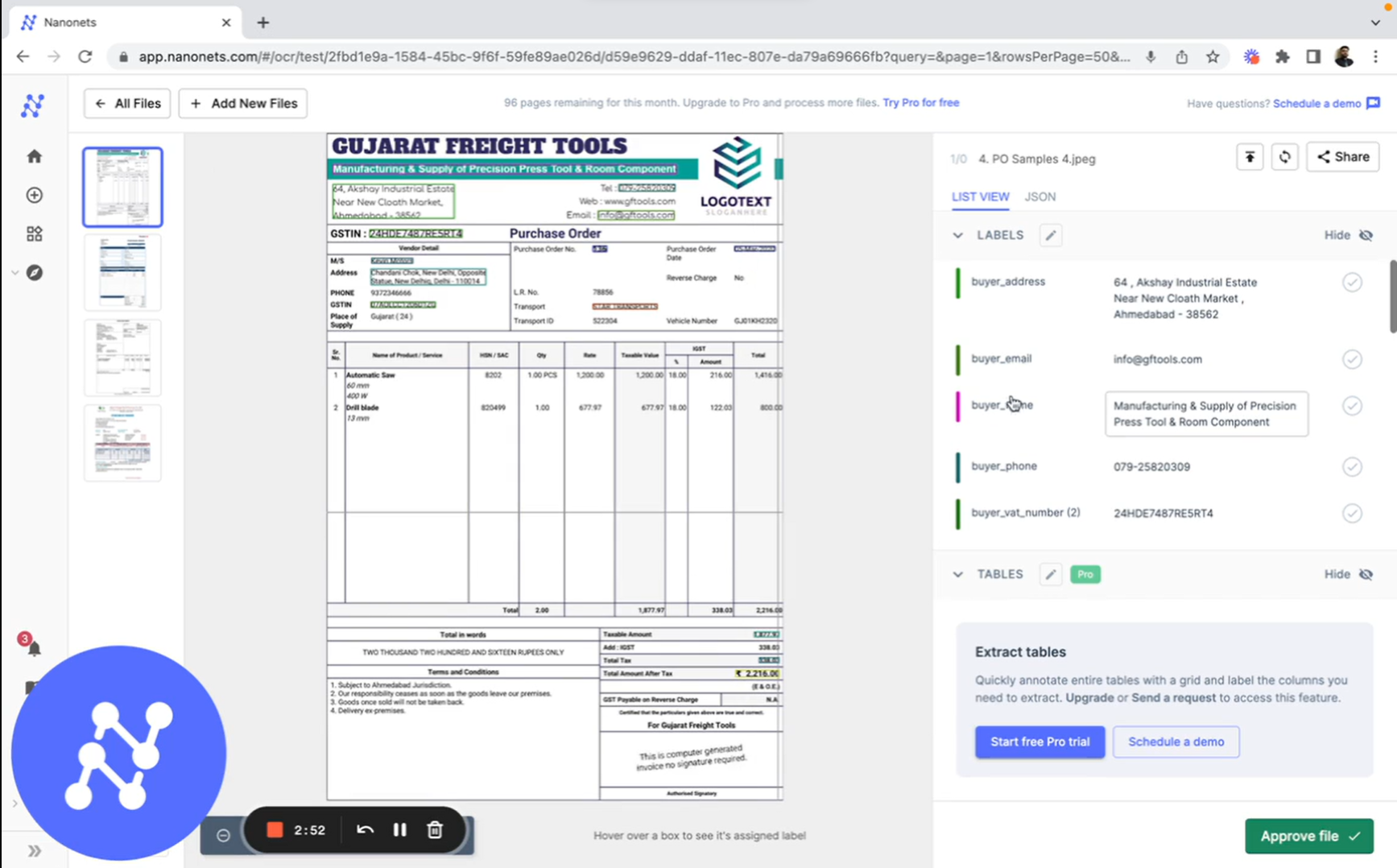

Looking to automate your manual AP Processes? Book a 30-min live demo to see how Nanonets can help your team implement end-to-end AP automation.

How strategic sourcing works

Strategic sourcing and procurement is a long-term process. To be implemented efficiently, organizations need to involve a proactive approach that can help assess business needs and perform spend analysis.

Strategic sourcing processes are not only limited to data collection and supplier evaluation but also focus on building a collaborative relationship with them. Companies must also perform periodical assessments with detailed market research to measure performance and align sourcing requirements accordingly.

Strategic sourcing considers all costs and benefits of a product/service over its lifecycle. This includes transportation, storage, maintenance, quality, warranty, disposal, and environmental impact. You'll be able to identify hidden costs, optimize spend, and develop long-term supplier relationships by analyzing the true cost of ownership.

The methodology followed in strategic sourcing and procurement may slightly vary among businesses but is mostly based on what is termed as the ‘7-step sourcing strategy’.

The 7-step sourcing strategy

The seven-step sourcing strategy developed by A.T Kearney is the most popular and time-tested method used among organizations, irrespective of the purchasing size. Here’s how the 7-step sourcing strategy works:

1. Profiling the spend category: Identifying the sourcing category involves understanding the requirements of goods or services in terms of quantity, size, and other specifications, along with the current pricing from various suppliers. User’s requirements, their location, etc. can help provide good insight for better spend analysis.

2. Perform supply market analysis: An organization needs to engage in a supply market analysis to gain insight into the vendors’ market. This can help with a better understanding of the competition present, risks involved, supplier capabilities, and investment potential for better bargains.

3. Establish a sourcing strategy: This is a crucial step that decides the selection of vendors to get the maximum possible benefit with minimum risk. Companies should understand how existing vendors operate, the potential of new suppliers, and whether they can meet the requirements to align strategic procurement with the company’s business goals.

4. Choose the right sourcing process: Organizations use a bidding process to get proposals from vendors to get the best possible quotes for the supply of goods and services. The most popular method used for this is Request for Proposal (RFP). RFPs aid in a data-driven approach to shortlist suitable suppliers. RFPs detail product or service requirements, estimated budget, evaluation criteria, and other terms and conditions. Companies can also ask for a Request for Information (RFI) after RFPs to narrow down the selection of suppliers.

5. Negotiate contract terms: Once companies shortlist potential suppliers, the next step is to negotiate terms that can be beneficial for the company as well as the vendor. It may involve multiple rounds to arrive at the best possible contract terms that can include pricing, delivery time-frames, payment periods and terms, quality standards, and more.

6. Communicate, implement, and integrate: Once the contract negotiations are successful, organizations need to ensure that there are proper communication channels established to make sure everyone is on the same page. Onboarding of new vendors, integration of suppliers into discussions, communicating changes, if any, are all vital in making the implementation stage effective.

7. Benchmarking: The final step in this long process necessitates continuous monitoring to ensure that supplier performance conforms to expectations and contract agreements. Tracking helps to identify lapses that can be addressed immediately with the supplier to prevent additional costs and ensure business goals are met accordingly.

All organizations, irrespective of whether they purchase raw materials or finished goods, normally use some form of this 7-step process to meet business requirements.

Set up touchless AP workflows and streamline the Accounts Payable process in seconds. Book a 30-min live demo now.

The various benefits of strategic sourcing

Strategic sourcing can be highly beneficial for an organization if implemented correctly. Highlighted are some of the advantages that companies can derive using a strategic sourcing and procurement process:

- Higher cost savings - The primary advantage of using a strategic sourcing process is that of significant savings on costs. The selection process helps to get better suppliers with ideal prices that can be beneficial for the company. Also by implementing a tracking process, additional costs and delays are averted resulting in increased savings.

- Lower risk and increased efficiency - Allocating time to understand the vendor markets can help ease procurement across geographical locations. This helps identify risks that can be reduced by developing appropriate sourcing plans to ensure better business efficiency. Implementing a monitoring process can also help lower risks of unexpected delays and extra costs that can affect business reputation.

- Optimized outcomes - The supplier selection process through detailed information analysis can result in procuring the best suppliers that can positively benefit the business goals of the organization. By roping in the right suppliers, companies are also better able to add value to their business at reduced cost and increased efficiency.

- Stronger vendor relationships - The strategic sourcing process also helps foster better business relationships between the purchaser and the supplier. Including suppliers in meetings and discussions during the implementation stage, provides them with a sense of value and motivation.

Strategic sourcing vs. Tactical procurement

While strategic sourcing and tactical procurement may be similar, they are different in certain aspects that are listed below:

- Tactical procurement is considered a short-term function that can help in meeting immediate business requirements. A strategic sourcing process is a long-term function that aims to make a company’s procurement process easier with lower risk and to build good supplier relationships.

- Tactical procurement involves planning and other related activities to acquire goods and services at the lowest possible cost. Strategic sourcing involves finding the ideal vendor sources for procuring goods and services to increase overall profitability.

- While tactical procurement is directly involved in activities that complete the cycle of ordering and receiving goods and services, strategic sourcing is a procurement subset that happens at the initial stage for procurement to be successful and cost-effective.

- Tactical procurement is not elaborate and does not require huge investments in terms of skilled manpower and technological assistance. Strategic sourcing involves detailed analysis to arrive at profitable solutions and hence requires highly skilled personnel and advanced technologies for successful implementation.

Book this 30-min live demo to make this the last time that you'll ever have to manually key in data from invoices or receipts into ERP software.

Artificial Intelligence and strategic sourcing

AI can aid in detailed analysis using cognitive capture on huge amounts of data to help with past performance evaluation, make impactful future forecasts, or collaborate and negotiate better deals with suppliers. Progressive tracking tools provide visibility and accuracy to make risk management easier.

Using automated solutions for strategic sourcing

Strategic procurement can be highly efficient and beneficial to organizations when using automated solutions. Digital transformation of data via automated solutions can make the strategic procurement process faster, simple, and result in savings on cost and human effort.

Organizations can adopt e-sourcing software solutions as part of the strategic sourcing and procurement process. This benefits them in many aspects right from online sourcing of bids to awarding contracts to selected suppliers. Automation offers complete solutions to handle various processes such as supplier identification, spend analysis, forecasting, contract management, etc.

Using automated solutions for strategic procurement can:

- Streamline complex processes such as spend analysis and provide better visibility to stakeholders to make informed decisions.

- Facilitate easier e-sourcing bids or RFPs to enlist more suppliers with competitive rates

- Provide faster negotiations that result in cost savings, signing of contracts through digital signatures, and maintaining a contract repository with timely renewal alerts.

- Minimize risk by setting compliances to reduce extra cost and delays

- Enable continual feedback for further analysis to gain optimized workflows

Conclusion

Strategic sourcing is fast catching up and required in the modern world to optimize sourcing functions in organizations, irrespective of their size. It helps them manage their sourcing requirements through supplier selection, mitigation of risks, savings on costs, and maximizing business efficiency. Using automated solutions (e-sourcing) with AI-based technologies can optimize sourcing processes to enhance performance and provide the competitive edge that businesses seek today.