Sourcing and procurement: The key differences

In the context of purchasing goods and/or services by an organization for its operations, the words sourcing and procurement are often interchangeably used.

While the two terms are indeed related, there are definite differences between them. In this article, we’ll see what procurement sourcing processes are, how they are different, and how they work together to enhance the overall operational efficiency of an organization.

What is procurement?

Procurement is the placement of orders with suppliers, confirming the orders, making the payment, and ensuring correct and timely delivery of the ordered product/service. It is the foundation of supply chain management. Without a sound procurement strategy, precious time is wasted in obtaining the basic products/services that organizations need to function.

The procurement management process typically involves a number of steps. Each step in the procurement process has risks and opportunities that must be carefully weighed. The process of procurement of goods and services is sometimes referred to as the Procure-to-Pay Cycle which is a subset of the larger Source to Pay cycle.

What is sourcing?

If the purchase process were a movie, sourcing is the prequel to procurement. It encompasses all activities related to finding the best supplier for goods and services before the procurement process can start. It includes identifying potential suppliers, vetting them, and selecting/engaging with the supplier who offers the best value in terms of price/quality of the required material.

Sourcing entails evaluation of the supply market, development of a procurement strategy and negotiation of terms and conditions of the purchase. It often ends with the signing of a contract or agreement between the company and the supplier about the product/service to be procured and the terms of the purchase.

Looking to automate your manual AP Processes? Book a 30-min live demo to see how Nanonets can help your team implement end-to-end AP automation.

The difference between sourcing and procurement

Sourcing and Procurement are pivotal processes for acquiring goods or services. Sourcing involves identifying products or services externally. Procurement, on the other hand, focuses on negotiating contracts to secure the best prices. Combining these processes enhances efficiency and cost-effectiveness for businesses, ensuring optimal resource utilization.

Sourcing is an enabler for procurement. Small enterprises often combine the two, where the purchase department is responsible for both - doing research on the suppliers, supplies and cost aspects, AND procuring from the selected vendors. However, as a business grows in size, these two operations are separated in order to reduce errors, save time, improve efficiency and benefit bottom lines.

Sourcing is all about managing information regarding the suppliers of goods/services required for a company’s operation, thereby building supply chain resilience. The tasks in sourcing include:

- Analysing the product/service requirement of the company

- Identifying potential vendors for the product/service

- Vetting vendors in terms of suitability to the company

- Maintaining a database of equivalent and alternative suppliers

- Requesting quotes

- Defining lead times

- Conducting negotiations and agreements on pricing

- Performing supplier risk analysis

- Devising purchase strategies for the company

The procurement part involves the actual purchasing of the product/services from the source/vendor/supplier. It involves activities such as:

- Assembling the purchase order process

- Ordering the product/service

- Tracking its delivery

- Confirming delivery as per specifications of the purchase order

- Paying for the product/service procured

The sourcing vs procurement relationship is not one-way, rather, it is a cycle. The data generated by the procurement team after the procurement process is fed back into the sourcing team. This feedback helps to better manage supplier relationships, judge supplier performance over time, and make strategic decisions on continuing or discontinuing relationships with that particular vendor.

The following points summarize the procurement vs sourcing comparison

Sourcing

Objective

-

Minimize risk and purchase cost

-

Process

-

Market analysis

-

Vendor analysis

-

Vendor database

-

Vendor selection

-

Contract development

-

Contract negotiation

-

Strategy design

Procurement

Objective

*Maximize return on investment

Process

- Requisition analysis

- Purchase order development

- Order placement

- Delivery tracking

- Payment

- Spend data and analytics

- Feedback to Sourcing

Set up touchless AP workflows and streamline the Accounts Payable process in seconds. Book a 30-min live demo now.

The difference between procurement, sourcing, and purchasing

While procurement and sourcing are often used interchangeably, purchasing is a distinct concept. Purchasing is just one step within the procurement process. It is the act of buying goods and services that the organization needs. This includes placing orders, receiving goods, and paying invoices.

In essence, sourcing is a strategic process that involves finding, evaluating, and engaging suppliers of goods and services. Procurement is a broader process that includes sourcing and involves ordering, receiving, and paying for those goods and services. On the other hand, purchasing is a transactional function that is part of the procurement process.

To illustrate this, let's consider an example:

Sourcing: A newspaper company is looking for a new ink supplier. They research the market, identify potential suppliers, assess their quality and pricing, and negotiate a contract with the most suitable one.

Procurement: The newspaper company, after securing the ink supplier, places an order for a specific quantity of ink, tracks the delivery of the order, verifies that the order meets the agreed specifications, and then processes the payment.

Purchasing: The act of placing the order for the ink and paying the invoice is the purchasing part of this process.

Understanding these distinctions can help organizations streamline their operations and manage their supply chains more effectively. It allows for more strategic decision-making, cost savings, and improved supplier relationships.

It's important to note that while procurement, sourcing, and purchasing are three separate processes, they are interconnected and rely on each other for the smooth operation of a business. The processes ensure a steady flow of goods and services, maintain good supplier relationships, and optimize costs.

Synergy of sourcing and procurement

It is no longer sourcing vs procurement, but sourcing AND procurement. Procurement sourcing processes have been historically viewed as back-office functions. There is a growing trend in looking at sourcing & procurement as strategic front-end functions because of the flexibility required to meet changing business demands. Strategic sourcing and procurement processes work together to ensure the following benefits:

Cost optimization: Sourcing teams maintain and analyse the database of vendors/suppliers and update the list of suppliers that suit the budget of the business. Procurement teams use the data provided by the sourcing team to buy products within the allocated budget. In reverse, the feedback provided by the procurement team about a vendor helps the sourcing team update the list of suppliers and their competence. Such synergy prevents runaway expenses and helps budgeting operations.

Supply stability: The procurement sourcing collaboration ensures stability of supply by advance planning and division of labor.

Risk Avoidance: With upscaling of businesses, the process of procurement must not only meet compliance standards but also tackle risk exposure, investments for risk mitigation and risk transfer pricing. A good sourcing department is necessary to dynamically manage new metrics, streamline sourcing and supply decisions, and ensure maximum ROI.

Sustainability: The supply chain must be robust in order to meet the demands of a rapidly changing market. This ensures strategies that go beyond cost-cutting and focus on sustainability over time in terms of maintaining consistent supply; and avoid interruptions to the operations of the business. Traditional linear supply chains must be swapped for circular ones to enable sustainability.

Globalization: With the gradual transformation of supply and demand trends in emerging markets, there is increasing pressure on large businesses to go global. Global presence would entail fitting to the supply chains of various countries. This demands a robust relationship between the sourcing and procurement divisions in each country.

Security: The security of information is important for companies to keep up with competition. Collaboration between sourcing and procurement teams is essential to ensure comprehensive supplier onboarding and offboarding processes. This, along with close monitoring and management of key suppliers can enhance the security of the supplier information maintained by the company.

Sourcing and procurement groups must work towards refining the outcomes of their synergy. For example, risk-related performance must be continually measured using operational metrics tied to the execution of risk-management processes.

How to improve sourcing and procurement

Building a great strategic sourcing plan and optimizing the procurement process requires a blend of careful planning, the right tools, and a strong understanding of your business's needs.

Here's how you can improve your sourcing and procurement processes:

1. Understand your business needs

This includes knowing the products or services you need, the quantity, and the quality standards. Understanding this will help you identify the right suppliers.

Ask yourself the following questions:

- What are the key products or services that my business relies on?

- How much of these products or services do I need on a regular, recurring basis?

- What is the quality standard that these products or services must meet?

- Are there any legal or regulatory requirements that these products or services must comply with?

- What is the maximum budget allocated for these products or services?

2. Conduct a thorough supplier research

Investigate potential suppliers to determine their reliability, quality of products, and pricing. Use online tools and resources to gather information about different suppliers.

For example, you could use:

- Supplier directories and databases

- Online reviews and ratings

- Industry reports and analysis

- Case studies and testimonials from other businesses

- LinkedIn profiles and other social media platforms of potential suppliers

3. Establish a strategic sourcing plan

This plan should include a detailed procurement strategy focusing on cost reduction, quality improvement, and supplier relationship management. It should also include a procedure for managing supplier contracts and performance, as well as contingency plans for supply chain disruptions.

Some things to consider when creating your strategic sourcing plan:

- Which suppliers can meet my business needs in terms of quality, quantity, and price?

- How will I manage and evaluate supplier performance?

- What are my contingency plans if a supplier fails to deliver as expected?

- How will I manage supplier contracts and negotiations?

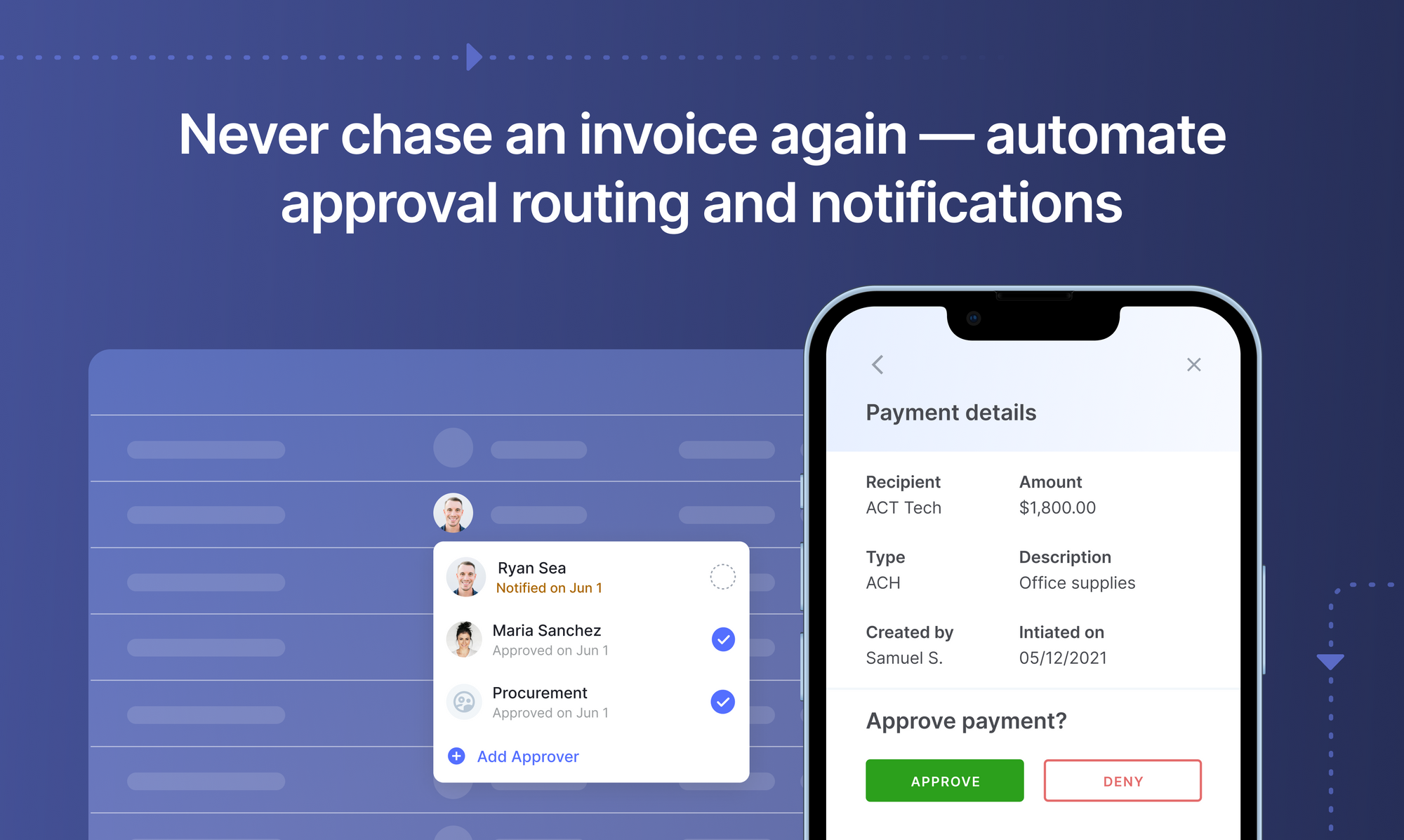

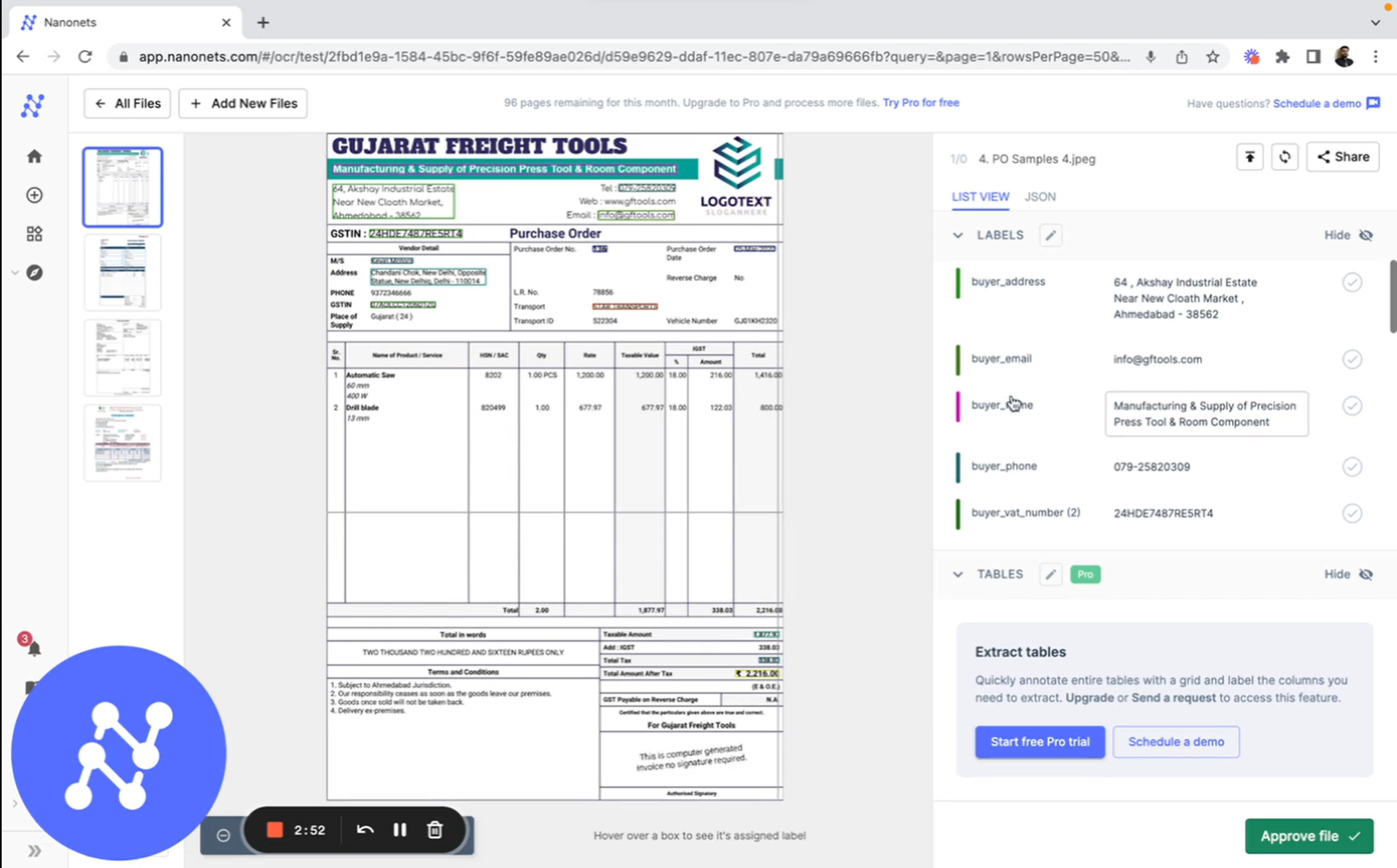

4. Leverage automation

Automating procurement processes can drastically reduce manual workload, improve accuracy, and enhance efficiency. Automation tools can help in areas like purchase order processing, invoice management, contract management, and supplier performance tracking.

Consider using procurement software like Coupa, SAP Ariba, or Nanonets to streamline your procurement process. These tools offer features such as:

- Automated purchase order creation and tracking

- Supplier management and evaluation

- Contract management

- Invoice processing

- Inventory management

5. Continually monitor and improve your strategies

It's important to regularly review and update your sourcing and procurement strategies based on supplier performance, market conditions, and business needs. Use metrics and KPIs to measure the effectiveness of your strategies.

Here are a few metrics you might consider:

- Cost savings: Measure the difference between what you would have spent without the sourcing strategy and what you actually spent.

- Supplier performance: Track metrics like on-time delivery rate, defect rate, and compliance with contract terms.

- Procurement cycle time: Measure the time it takes from the start of the procurement process to when the product or service is received.

- Internal customer satisfaction: Survey your internal customers (such as department heads or project managers) to gauge their satisfaction with the procurement process.

6. Foster strong supplier relationships

Building strong relationships with your suppliers can lead to better prices, improved quality, and reliable deliveries. Regular communication and feedback, as well as recognizing and appreciating their efforts, can greatly enhance supplier relationships.

For example, you can:

- Schedule regular meetings or calls with your suppliers to discuss performance, address concerns, and explore opportunities for improvement.

- Provide constructive feedback and recognition for a job well done. This can be as simple as sending a thank you note or mentioning them in your company newsletter.

- Establish a clear dispute resolution process. This ensures that any issues are addressed promptly and professionally, helping to maintain a positive relationship.

- Invite suppliers to company events or include them in relevant training sessions. This not only strengthens the relationship but also gives them a better understanding of your business and its needs.

Software solutions for sourcing and procurement

Technology and automation can facilitate collaboration between sourcing and procurement groups with their ability to collate data/facts/information/analytics and provide easy access to all stakeholders. Automation can ensure continuity in supplier relationships, support analytical decision making, provide access to data across the business and supplier base, and set strategies and conditions to maximize value for money. Automation can also ensure that strategic sourcing capabilities can be scaled up in order to prevent lags and delays in business outcomes.

Benefits of sourcing-procurement software

Some benefits of sourcing-procurement software are:

- Improved speed and efficiency

- Availability of all purchase data in one place

- Better control and visibility of data across the business

- Instant access to all purchase-related documentation

- Better inventory management that would avoid shortages and over-stocking

- Enhanced Budgeting due to built-in analytics solutions and automated report generation

- Organized supplier management

While technological support is already extensively available for the transactional areas of sourcing and procurement – in the execution of the procure-to-pay processes, the use of software in the sourcing (e-sourcing) process is gradually gaining importance. A comprehensive software that handles the procurement sourcing can accelerate savings and impact realized from the enterprise spend, enable seamless collaboration with all stakeholders, and offer access to data to all stakeholders. It can also provide a comprehensive database of information about vendors, supplies, needs and buying trends for planning purposes.

Features of sourcing-procurement software

A comprehensive sourcing-procurement software is one that possesses all or most of the following features:

- Database of vendors/suppliers with rankings and ratings with respect to the company’s requirements

- Automated requests for quotes

- Budgeting capabilities

- Collaborative access to data

- Security checks at various levels

- Generation and management of purchase requisition

- Generation and management of purchase orders and contracts.

- Storage of all relevant information as tables in databases, with cross references between product/service specifications, vendor information, purchase requisitions, orders and receipts and other documents related to any procurement process

- Choice of storage of data in cloud or local server as per the company’s needs.

Book this 30-min live demo to make this the last time that you'll ever have to manually key in data from invoices or receipts into ERP software.

How to automate the sourcing-procurement process?

The decision of what software to use for sourcing-procurement depends on a few factors:

- Budget and spend oversight: This depends on the scale of the business, the bottom line and the investment potential of the company. The trade-off between investing in a sourcing-procurement software and budgeting allowed in the company must be analysed before deciding the type of software to be bought.

- Ease of use: It must be remembered that training and set-up expenses are the biggest blocks to implementing any kind of automation in a process workflow. The skill level of the employees using the software will decide how user-friendly the front end of the software should be, and the level of tech support that will be required of the developer.

- The level of automation: It is important to check the features provided by the tool, such as digital form creation, complex routing, and online approvals. Each company has its own requirements and styles when it comes to the purchase process. The ability of the software to incorporate the company’s practices and policies must be assessed.

- Easy collaboration for teams: Since at least two teams are involved in the sourcing-procurement cycle, the software must be able to provide access at various levels and allow easy collaboration among the stakeholders. There also needs to be provision to include various levels of approvals in the process.

- Integration with the other systems used in the company: The software must integrate with the other systems such as accounting management tools used already in the company. Stand alone sourcing-procurement software that does not integrate with the digital tools used in accounting and marketing departments would lead to data mismanagement and time loss.

The process of sourcing-procurement automation must include the following steps:

- Mapping of the current sourcing-automation workflow to understand the steps and stakeholders involved in the process. Business Process Modeling Notation (BPMN) could be used to map out the steps of the existing workflow as a flowchart.

- A complete audit of the sourcing-procurement process will help identify pain points in the workflow that cause time delays and bottlenecks. This will help in deciding the features required of the software during automation.

- Choosing the sourcing-procurement software that best fits the needs of the company. If the company has multiple locations, the automation software must be capable of being accessed from anywhere and cloud storage would fit the situation.

- Building sourcing-procurement automation workflow. This will help in seamless transition into automation and prevent loss of time in adjusting to the new workflow.

- Measure and improve: Constant appraisals of the software’s performance will help optimize the system and avoid errors in this most important function of any organization.

Conclusion

There is now a move in many upwardly mobile companies to automate their critical functions. The automation of procurement sourcing (or e sourcing) saves time and manual effort, cuts back on costs, improves record-keeping, and streamlines vendor relationships. The time and money saved by automation can be rerouted to other productive areas that need manual intervention, and thus improve the bottom-line of the company.

FAQs

What does sourcing and procurement do?

Sourcing and procurement are critical processes in any organization. Sourcing involves identifying, evaluating, and establishing relationships with suppliers to acquire goods or services. It's a strategic aspect that focuses on long-term partnerships with vendors.

Procurement, on the other hand, is the process of purchasing goods or services from these suppliers. It involves order placement, delivery tracking, invoicing, and payment processing.

Together, sourcing and procurement ensure a steady flow of materials and services necessary for the company's operations.

Which comes first, sourcing or procurement?

Sourcing typically comes before procurement. The sourcing process involves identifying potential suppliers, evaluating their capabilities, and negotiating contracts. Once the sourcing process has established supplier relationships, the procurement process begins. This involves placing orders with the suppliers, tracking deliveries, handling invoices, and managing payments.

What is purchasing vs sourcing vs procurement?

Purchasing is the act of buying goods or services. It's a transactional process that

includes order placement and payment processing.

Sourcing is a strategic process that involves identifying potential suppliers, evaluating their capabilities, and establishing relationships with them.

Procurement encompasses both sourcing and purchasing. It's an end-to-end process that starts with sourcing and ends with delivering goods or services.