The ultimate guide to procurement management

Procurement management is more than just buying goods or services at the best price — it is about optimizing organizational spending, from identifying needs to vendor selection, contract negotiation, and more. Whether you're a mom-and-pop shop owner or a seasoned procurement pro, better procurement management could be your ticket to a leaner, more cost-effective business operation.

Imagine running a bustling Italian restaurant. Here, procurement management isn't just about ordering heaps of produce. It's about sourcing the freshest fruits and veggies, purchasing the right sauces that make your dishes stand out, and scoring the best deals on those vintage wines.

It’s about getting the right stuff, at the right price, and at the right time.

For any company, whether a hospital, a construction firm, or a tech giant, procurement means the difference between smooth operations and costly disruptions.

Late procurement equals a halted production line — a straight shot to financial losses, messing up your project management timeline, and a hit to your reputation. It’s that straightforward. Procurement isn’t glamorous; it’s gritty negotiations, meticulous planning, and strict budgeting. But when done right, it’s the backbone of profitability.

This blog post discusses the practicalities of procurement management, breaking down the process, highlighting the benefits, and making a case for automated workflows in procurement.

What is procurement management?

Procurement management is the process of sourcing and acquiring goods or services that an organization requires for its operations from external sources. It is part of the entire source-to-pay cycle.

In its simplest form, procurement management involves identifying a company's needs, finding and evaluating potential suppliers, negotiating terms and prices, making purchases, and ensuring that the procured items meet the required standards and are delivered on time.

In practice, procurement management is a strategic function that includes supplier relationship management, contract management, budgeting, and risk management. It also impacts project management and supply chain management, affecting the efficiency of operations, cost savings, and overall business performance.

A single person might handle procurement in smaller firms, while larger organizations boast dedicated departments.

The importance of procurement management

With only 6% of companies reporting complete visibility on their supply chain and 43% of small businesses not tracking their inventory at all, it's clear that good procurement management can make or break a company's operations.

Effective procurement management is essential for several vital functions within a business.

- The purchase requisition process demands meticulous attention, ensuring that every detail is accurately recorded and policies are followed. This step sets the stage for efficient procurement by guiding users through requisitioning and suggesting suitable vendors.

- Purchase orders, when meticulously managed, serve as a blueprint for procurement, detailing product specifications and terms. Clear, well-documented purchase orders foster smooth supplier communication, minimizing misunderstandings and delays.

- Invoice approval, a critical step in the procurement cycle, necessitates scrutiny to validate accuracy and adherence to agreed-upon terms. Proper invoice processing prevents financial discrepancies and strengthens supplier relationships.

- Effective vendor management involves regular assessments, ensuring suppliers meet quality and reliability standards. This proactive approach establishes long-term, fruitful partnerships.

- Contract approval and management demand precision, where contracts are scrutinized for compliance, protecting the business from legal and financial risks.

- Inventory management requires vigilant monitoring to maintain optimal stock levels, preventing overstocking or understocking, which can disrupt operations and strain budgets.

- Project management also benefits from procurement management, as timely procurement of necessary resources directly impacts a project's success. Proper procurement management ensures the availability of required materials, tools, or services as and when needed, thus keeping the project on schedule.

Procurement management is the guiding force in every step, from requisition to supplier payments. The procurement managers ensure the company gets the best bang for its buck. They source top-quality materials, negotiate the best prices, and build lasting relationships with suppliers.

Procurement management is a tool for controlled spending and improved efficiency.

The benefits of effective procurement management

A recent KPMG report revealed that 67% of organizations consider meeting customer expectations for speed of delivery as a critical force impacting the structure and flow of their supply chains over the next 12-18 months.

This statistic underscores the benefits of effective procurement management. Procurement management can streamline processes, save time, reduce costs, and improve a company's bottom line when well-executed.

Some specific benefits include:

1 . Cost reduction

- Strategic planning: Thoughtful procurement planning involves analyzing market trends, demand fluctuations, and vendor behaviors. Companies can significantly reduce their procurement spending by strategically timing purchases and selecting the right vendors.

- Negotiating power: Armed with detailed planning and adequate time, the procurement team possesses more substantial negotiation leverage. This strategic advantage enables them to secure contracts and bulk deals with more favorable terms, ensuring significant cost savings.

- Vendor relationship management: Maintaining positive relationships with suppliers, especially those in long-term contracts, can lead to preferential pricing and discounts, further reducing procurement expenses.

2. Enhanced resource continuity

- Long-term planning: Effective procurement management involves forecasting long-term resource requirements. By anticipating needs well in advance, businesses can establish reliable supply chains, preventing interruptions and ensuring consistent operations.

- Supplier diversification: Relying on a diverse pool of suppliers mitigates risks associated with dependencies on specific vendors. In case of shortages or disruptions, alternative suppliers can step in, maintaining the flow of resources without significant interruptions.

- Quality assurance: Procurement management involves evaluating vendors for their reliability, quality of goods or services, and delivery timelines. This ensures the business procures high-quality goods or services that meet its requirements.

3. Streamlined operations and transparency

- Stakeholder collaboration: Transparent procurement encourages open stakeholder communication, fostering collaboration and efficient issue resolution. Clear communication channels ensure that all parties are well-informed, minimizing misunderstandings and delays.

- Data-driven decision-making: Businesses can gain insights into their procurement processes by leveraging data analytics and procurement software. Analyzing this data enables informed decision-making, optimizing processes, identifying bottlenecks, and enhancing overall efficiency.

- Process automation: Implementing procurement software can automate repetitive tasks, reducing manual errors and saving time. Automated processes also provide real-time tracking of procurement activities, ensuring timely execution and maintaining transparency.

4. Risk mitigation framework

- Comprehensive risk assessment: Robust procurement management involves conducting thorough risk assessments encompassing financial, operational, legal, and strategic aspects. Identifying potential risks enables proactive measures, minimizing their impact on procurement activities.

- Contingency planning: Developing contingency plans for identified risks ensures swift responses in case of disruptions. Predefined strategies for various scenarios enable businesses to navigate challenges effectively, maintaining supplier relationships and operational continuity.

- Compliance tracking: Strict adherence to regulatory standards and internal policies is critical in procurement management. Regular compliance audits, coupled with corrective actions, mitigate legal risks and protect the organization's reputation.

5. Supply chain resilience

- Proactive approach: Shifting from a reactive "just-in-time" approach to a proactive "just-in-case" mentality involves stockpiling critical resources to address unforeseen disruptions swiftly. This approach ensures a buffer, allowing businesses to continue operations seamlessly during emergencies.

- Flexibility and adaptability: A resilient supply chain requires flexibility. Businesses must be ready to adapt to changing market conditions, supply chain dynamics, and emerging challenges. By staying agile, organizations can adjust their procurement strategies promptly, ensuring a continuous flow of resources.

- Sustainable procurement: Adopting sustainable procurement practices contributes to supply chain resilience. By sourcing from stable, ethical, and environmentally friendly suppliers, businesses can ensure a reliable supply of resources, even during disruption. This practice also aligns the organization with global sustainability efforts, enhancing its reputation and providing a competitive advantage.

6. Empowered innovation focus

- Long-term investment: Efficient procurement management frees up financial and human resources, allowing businesses to invest in research and development. Long-term investments in innovation yield sustainable growth, enabling companies to explore new markets, products, and technologies.

- Strategic partnerships: Allocating resources to strategic alliances and collaborations fosters innovation. By collaborating with innovative suppliers, businesses can access cutting-edge products and services, enhancing their competitive edge in the market.

- Technological innovation: Incorporating AI, OCR, and machine learning can significantly improve procurement processes. Such technologies can streamline tasks, improve data accuracy, automate processes, and provide predictive insights, leading to efficient and effective procurement management.

7. Project management and execution

- Timely execution: With efficient procurement management, businesses can ensure that all essential resources are available when needed, enabling smooth project execution. This reduces project delays and helps in maintaining the project schedule.

- Resource optimization: Effective procurement allows for optimal use of resources, reducing wastage and leading to cost savings. It also ensures that the right resources are available at the right time, thereby increasing project efficiency.

- Stakeholder satisfaction: Timely and efficient procurement leads to stakeholder satisfaction. By ensuring the timely availability of resources and maintaining transparency in procurement processes, businesses can build trust and maintain good relationships with stakeholders.

The procurement management process

The procurement management process is a systematic approach to procurement that includes several essential steps.

This process helps businesses manage their procurement activities efficiently, ensuring they acquire goods or services that meet their requirements at the most cost-effective price.

1. Specifying and planning

- Establishing needs: Determine the products or services required for business operations, considering existing data and future projections.

- Setting specifications: Clearly define the specifications of the products, ensuring suppliers understand the exact requirements.

- Strategic forecasting: Plan for the ordering and reordering processes, aligning with demand forecasts and operational timelines.

Let’s take an example of a restaurant procuring ingredients for its menu. The restaurant would first identify the ingredients needed based on their menu and customer preferences.

Then, they would specify each ingredient's quality, quantity, and delivery timelines. Finally, they would forecast their needs based on anticipated customer demand and seasonal variations, planning their orders accordingly.

2. Identifying and selecting suppliers

- Research and evaluation: Conduct comprehensive research to identify potential suppliers based on criteria like quality, reliability, and cost-effectiveness.

- Vendor selection: Choose suppliers through competitive bidding or established relationships, ensuring diverse options for a resilient supply chain.

- RFx process: Initiate the Request for Information/Proposal/Quotation process to assess supplier capabilities and offerings.

Here are a few questions to ask potential suppliers during the selection process:

- What is your track record in delivering quality products/services?

- Can you meet our specifications consistently?

- How do you handle disruptions in the supply chain?

- What is your capacity to scale up or down based on our needs?

- Do you adhere to ethical and sustainable practices?

3. Negotiating and contracting

- Price and terms negotiation: Negotiate to secure the best price and contract terms, balancing quality and cost-effectiveness.

- Clear communication: Communicate requirements transparently, ensuring both parties have a shared understanding of expectations.

- Finalizing contracts: Document all agreed-upon terms and conditions, finalizing the agreement to formalize the partnership.

Here’s a quick checklist to manage the negotiation and contracting phase better:

- Have you compared the prices offered by different suppliers?

- Did you discuss delivery timelines and payment terms?

- Was the quality of products/services discussed and agreed upon?

- Did you consider the potential impact of unforeseen disruptions?

- Did you ensure that all terms and conditions are clearly documented in the contract?

4. Placing the Purchase Order

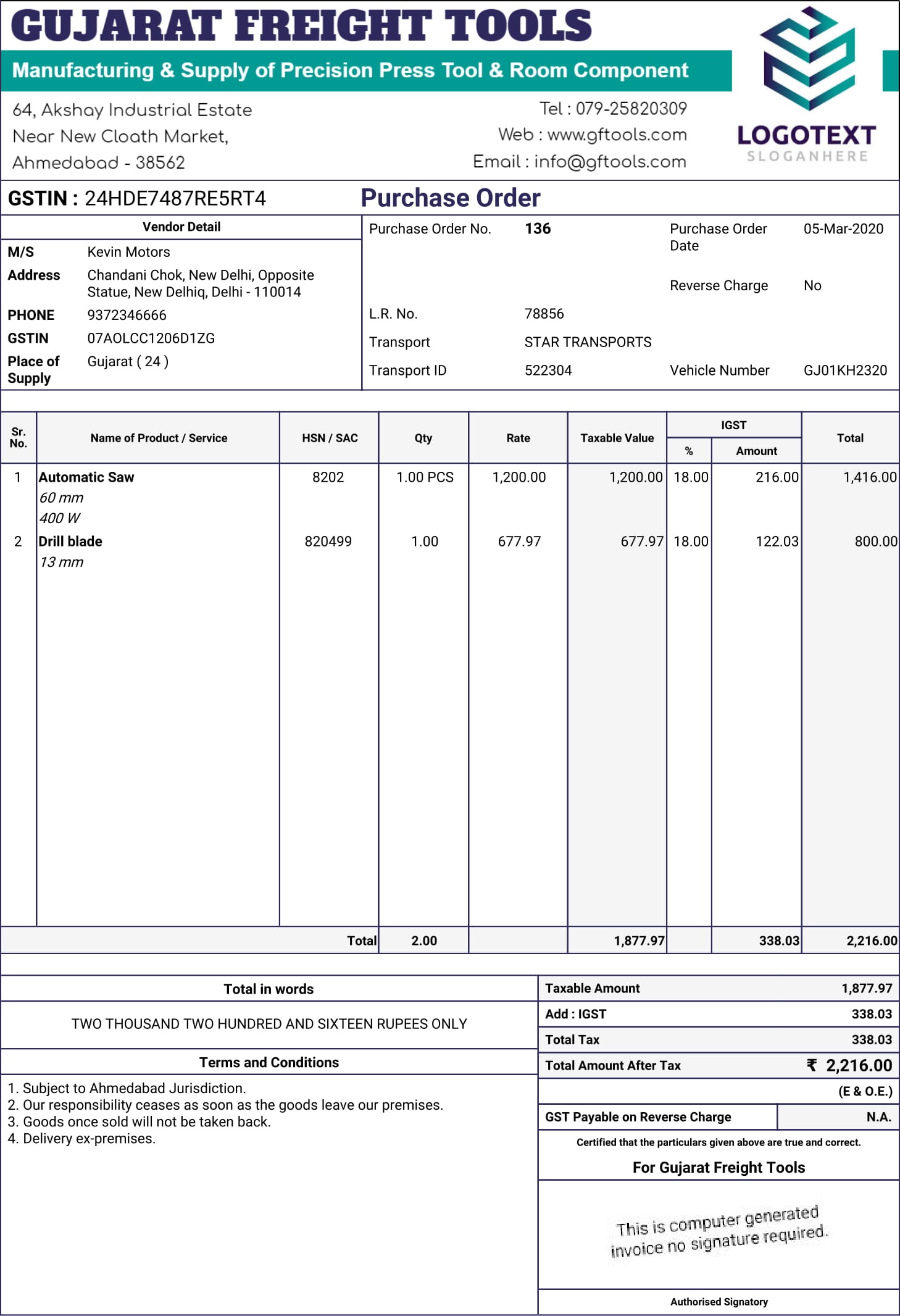

- Defining details: Specify product details, price, and terms in the Purchase Order (PO), ensuring clarity for both supplier and buyer.

- Source of truth: The PO acts as a reference point, validating the products and services to be procured and guiding all subsequent steps.

- Order placement: The PO is then issued to the supplier, signaling the official request for the specified goods or services.

Always review your Purchase Order meticulously before sending it to the supplier. A single error can lead to significant misunderstandings, delays, or financial losses.

5. Expediting

- Timely delivery: Ensure products are delivered promptly, addressing unforeseen circumstances such as product obsolescence or scheduling changes.

- Issue resolution: Address delays or discrepancies, maintaining clarity on payment dates, delivery schedules, and completion of work.

- Order tracking: Regularly track the order's progress and communicate any changes or updates to the supplier to ensure smooth operations.

Here are some expert tips to manage the expediting process better:

- Implement a robust tracking system to monitor the status of orders.

- Maintain constant communication with suppliers to address any issues promptly.

- Ensure clarity on the terms of delivery, including location, dates, and responsibilities.

- Develop a contingency plan to handle delays or unexpected changes in the order.

6. Receipt and inspection of purchase

- Quality review: Assess received products against established specifications and quality standards, ensuring they meet the defined criteria.

- Three-way match: Verify alignment between the PO, invoice, and packing slip/receiving document, highlighting discrepancies, if any.

- Inspection: Perform a detailed inspection of the goods, checking for any damages or defects before accepting the delivery.

Consider the case of a manufacturing company receiving raw materials from a supplier. The company would verify the quality and quantity of the materials, cross-checking these with the details mentioned in the PO and the supplier's invoice. If any discrepancies are found, they will be highlighted immediately to the supplier for resolution.

7. Invoice clearing and payment

- Document verification: Cross-verify the PO, invoice, and receiving documents, ensuring all details match accurately.

- Payment processing: Align purchasing and accounts payable, completing the payment process after confirming document alignment.

- Discrepancy resolution: Resolve discrepancies in the invoices or delivery documents before payment. This could involve discussions with the supplier or internal stakeholders.

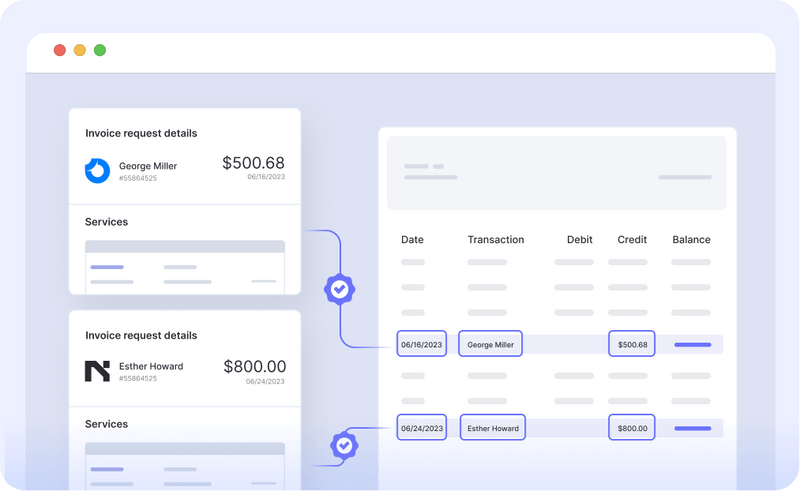

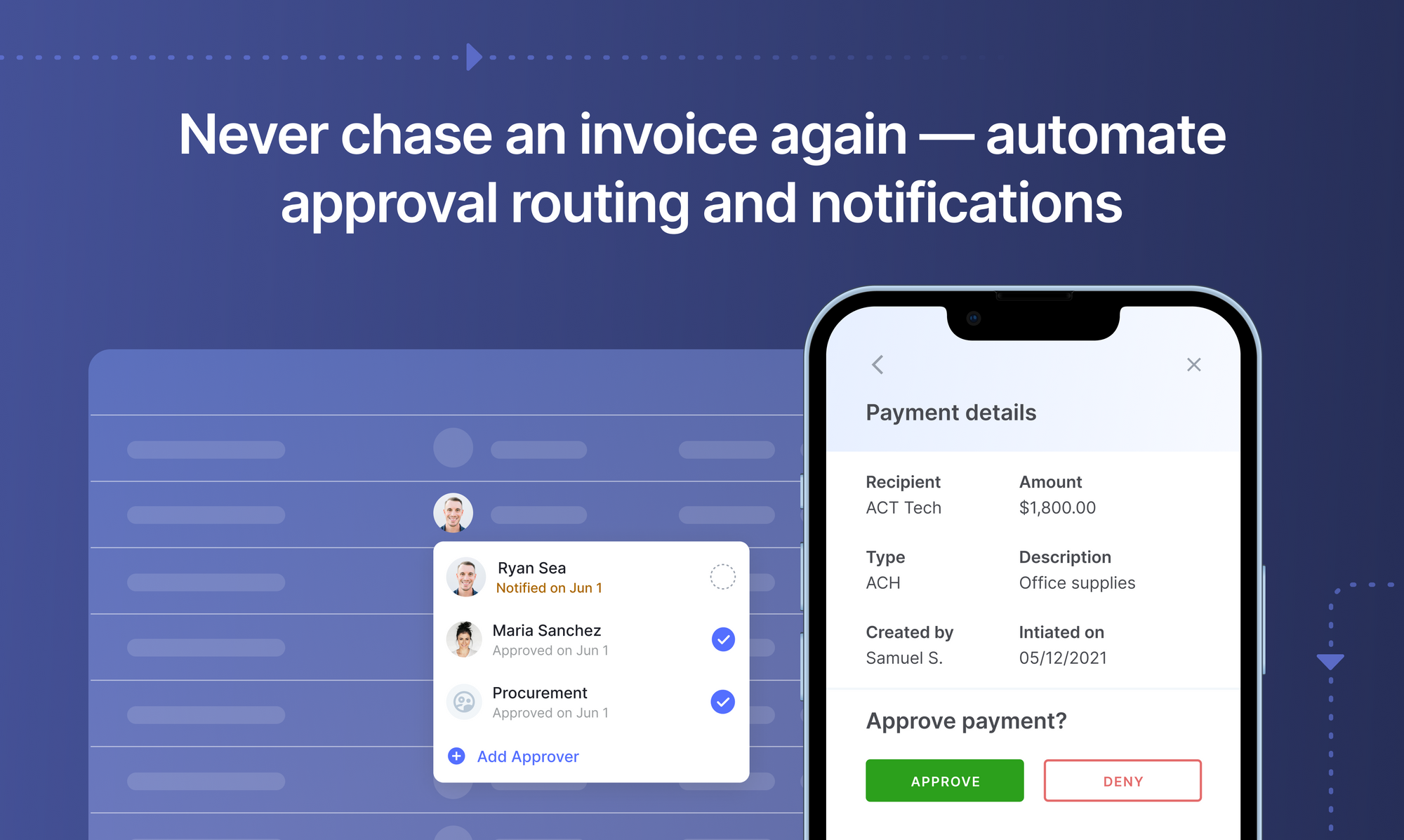

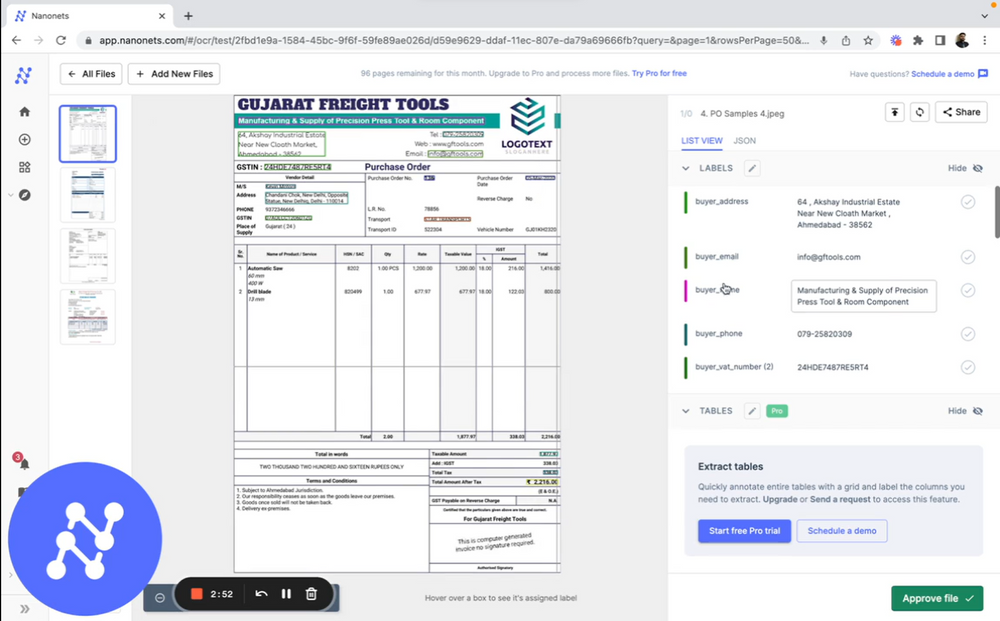

Expert tip: Use an AP automation software like Nanonets to streamline the invoice verification and payment. It comes with OCR and AI capabilities that can automatically extract and validate information from invoices, reducing manual effort and errors.

8. Maintaining records and relationships

- Record keeping: Maintain meticulous records for auditing, tax purposes, warranty validation, and future reordering references.

- Supplier feedback: Provide data and feedback to suppliers based on key performance indicators, fostering continuous improvement and mutually beneficial relationships.

- Performance evaluation: Regularly assess supplier performance for timely delivery, quality, and adherence to contract terms. This will aid in future vendor selection decisions.

Consider the following during this phase:

- Do you have a systematic way of archiving purchase orders, invoices, and delivery documents?

- Are you regularly assessing supplier performance and providing constructive feedback?

- Do you have a plan for addressing supplier underperformance?

- Are you maintaining good supplier relationships to ensure long-term collaboration and growth?

Establishing standard procurement policies enhances team reliability and trust. Review and update these policies regularly to adapt to changing circumstances. Consistent supplier performance evaluations and feedback loops can improve supplier relationships and service quality.

Remember, effective procurement doesn't end with the payment process. The final step involves record-keeping and relationship maintenance, ensuring a smooth procurement cycle for future transactions. By following these steps, you can create a streamlined, efficient procurement process that saves time, reduces errors, and significantly improves your organization's bottom line.

The different types of procurement contracts

Procurement contracts are legally binding agreements between buyer and seller. They sketch out terms, defining buyer-seller relationships. Many types exist, tailored to an organization's needs.

Here's a rundown of some commonly used procurement contracts:

1. Fixed price contract

This type of contract involves a set price for the goods or services being procured, regardless of the actual costs incurred by the supplier. It provides financial certainty for the buyer but can lead to issues if the supplier's costs exceed the agreed price.

An example of a fixed-price contract would be a furniture company agreeing to supply 100 chairs for $5,000. Even if the production costs fluctuate, the supplier must deliver the specified quantity at the agreed price.

2. Cost-reimbursement contract

Under this contract, the buyer agrees to cover the supplier's actual costs plus a fee or profit. While this can benefit complex projects with uncertain costs, it also carries a risk of cost overruns.

An example of this might be a construction project where the exact costs can't be predicted in advance. The organization would agree to reimburse the construction company for their actual costs plus an agreed-upon profit margin.

3. Time and materials contract

This type of contract is often used for projects where it's impossible to estimate the amount of time and resources needed accurately. The buyer agrees to pay the supplier based on the time and materials used. However, this type of contract can lead to cost overruns if not appropriately managed.

For instance, an IT company hired to develop a custom software solution would be paid based on the hours worked and the materials used.

Procurement management KPIs and metrics to track

Procurement management KPIs (Key Performance Indicators) and metrics are essential tools to evaluate the efficiency and effectiveness of your procurement process.

They help identify improvement areas, facilitate strategic decision-making, and enhance overall performance.

Here are some crucial KPIs and metrics to track:

1. Compliance rate

This metric measures how closely your procurement activities align with your organization's policies, procedures, and standards.

For example, if your policy requires three quotes for every purchase above a certain amount, the compliance rate would indicate the percentage of assets where this rule was followed.

A high compliance rate indicates that your procurement process is functioning as expected and adhering to internal guidelines.

2. Supplier defect rate

This metric evaluates the quality of goods or services received from suppliers. It's calculated as the number of defective items divided by the total number of items received.

For instance, if you receive 100 units from a supplier and five are defective, your supplier defect rate would be 5%.

A high supplier defect rate could indicate issues with the supplier's quality control and may require a review of your relationship with them.

3. Purchase order cycle time

This measures the time taken from when a purchase order is issued until the goods or services are received. It's a key indicator of efficiency in your procurement process.

For example, if your average purchase order cycle time is 30 days, it typically takes a month from issuing a purchase order to receiving the goods or services.

A shorter cycle time can indicate a more efficient process, while a longer cycle time may suggest areas for improvement, such as supplier responsiveness or internal approval processes.

4. Cost savings

This metric tracks the difference between the initial cost estimate and the final cost paid for goods or services. It's crucial for assessing the financial effectiveness of your procurement process.

For instance, if you initially estimated a purchase to cost $10,000, but through effective negotiation and supplier selection, you only spent $9,000, your cost savings would be $1,000 or 10%.

A higher cost savings percentage indicates that your procurement team effectively reduces costs through negotiation and strategic supplier selection.

5. Supplier lead time

This KPI measures the time it takes from placing an order until the goods are delivered. It's an important metric to track as it impacts inventory levels and can affect customer satisfaction.

For example, if your supplier typically delivers an order in two weeks, this would be your supplier lead time. If lead times start to increase, it may be a sign of problems with the supplier's production process or logistics, potentially necessitating a search for alternative suppliers.

6. Procurement ROI

This KPI measures the financial return on the investments made in the procurement process. It's calculated by subtracting the cost of procurement from the savings generated and then dividing it by the cost of procurement.

For example, if your procurement process costs $50,000 to operate and generates $200,000 in savings, your procurement ROI would be ($200,000 - $50,000) / $50,000 = 3 or 300%. This means that you generate three dollars in savings for every dollar spent on procurement.

A higher ROI indicates a more effective and efficient procurement process, generating significant financial benefits for your organization.

7. Spend under management

This metric measures the percentage of total company spend that is managed by the procurement department. It helps in assessing the impact of procurement activities on the overall company spend.

For example, if your organization's total spend is $1 million and the procurement department manages $750,000 of that, your spend under management would be 75%.

A higher percentage indicates a greater control of the procurement department over the company's spend, which can lead to more opportunities for cost savings and efficiency improvements.

8. Inventory accuracy

This KPI assesses the precision of your inventory records by comparing the physical count of items in stock against what's recorded in your procurement management software.

For instance, if your records indicate you have 500 units of a product, but a physical count reveals you actually have 520, your inventory accuracy would be 96%.

A high accuracy rate signifies that your inventory management is reliable and that your procurement team clearly understands the available stock. Low accuracy, on the other hand, can lead to issues such as stockouts or excess inventory and should be addressed promptly.

9. PO and invoice accuracy

This KPI measures the accuracy of your purchase orders (POs) and invoices by comparing the details on the purchase order with the corresponding invoice.

For example, if you issue a PO for 100 units of a product at $10 each, but the invoice you receive lists 120 units at $10 each, there's an error in accuracy.

A high level of PO and invoice accuracy ensures a smooth procurement process and helps avoid discrepancies that could lead to payment delays or supplier disputes.

10. Emergency purchase ratio

This metric measures the frequency of emergency purchases compared to total purchases. An emergency purchase is typically an unplanned, urgent buy due to factors like unexpected demand or inventory shortages.

For example, if you make 10 purchases in a month, and 2 of them are emergency purchases, your emergency purchase ratio would be 20%.

A high emergency purchase ratio could indicate demand forecasting or inventory management issues. Regular emergency purchases can disrupt your procurement process and lead to higher procurement costs. Therefore, it's beneficial to keep this ratio as low as possible.

11. Supplier concentration

This KPI measures the percentage of your company's spend concentrated with a single supplier or a small group of suppliers. For example, if you spend $100,000 annually and $40,000 goes to one supplier, your supplier concentration with that supplier would be 40%.

A high supplier concentration may indicate a dependency on a specific supplier, which could pose risks if the supplier experiences issues. A diversified supplier base can help mitigate these risks.

12. Supplier performance score

This KPI assesses your suppliers' performance based on quality of goods or services, delivery time, and adherence to contract terms. The score is typically calculated using a weighted scoring system.

For example, if quality accounts for 50% of the score, delivery time 30%, and contract adherence 20%, a supplier delivering high-quality goods on time but not adhering to contract terms might score 80 %.

A high supplier performance score indicates that the supplier is reliable and effectively meeting your organization's needs. Any significant drop in the score may signal issues that need to be addressed promptly with the supplier.

These metrics offer a snapshot of your procurement process, highlighting strengths and areas for progress. Regularly monitoring these enables strategic optimization and enhances supplier relationships. Ultimately, this leads to substantial cost savings and efficiency improvements.

Procurement management best practices

Businesses need to optimize their procurement processes to ensure efficiency and cost-effectiveness. It could involve implementing centralized procurement systems, improving supplier relationships, or investing in digital procurement tools.

Here are some best practices to consider:

1. Centralize your procurement process

Centralizing procurement can lead to improved efficiency and cost savings. In a centralized system, all procurement activities are handled by a single department, which reduces duplication of effort and allows for better negotiation of prices due to bulk buying.

Here’s how you can get started:

- Conduct an audit of your current procurement process to identify areas of inefficiency and fragmentation.

- Develop a plan for centralizing procurement, including identifying key stakeholders, setting clear goals, and outlining the steps needed to achieve those goals.

- Implement the plan gradually, ensuring that all stakeholders are kept informed and that there's adequate training for those involved.

- Regularly review and adjust the centralized procurement process based on feedback and performance metrics.

2. Develop strong supplier relationships

Strong relationships with suppliers can lead to benefits such as better pricing, priority service, and improved communication. Suppliers are more likely to go the extra mile for companies they have a good relationship with.

Tips to strengthen supplier relationships:

- Keep your suppliers informed about your business plans, changes, and requirements. Regular communication fosters trust and mutual understanding.

- Prompt payment is a simple way to show respect to your suppliers. It also ensures that you maintain a good credit status with them.

- Share your feedback with suppliers, both positive and negative. It helps them understand your expectations better and allows them to improve.

- Acknowledge the excellent work done by your suppliers. It can be through a formal supplier recognition program or a simple thank you note.

- Maintain transparency with automated status updates on orders and payments. This helps avoid misunderstandings and builds trust.

- Set up automated reminders and payment systems to ensure on-time payments. This strengthens supplier relationships and reduces the risk of late payment penalties.

3. Invest in digital procurement tools

Digital procurement tools can significantly enhance the efficiency and effectiveness of your procurement process. These tools automate manual tasks, provide real-time visibility into procurement activities, and enable data-driven decision-making.

Identify areas for digitization in your procurement process, like order processing or spend analysis. Then, pick a digital tool tailored to your business needs, considering functionality, usability, cost, and scalability.

Tool recommendations: Nanonets (AP automation tool), Oracle Procurement Cloud (procurement management software), Procurify (spend management tool), and SAP Ariba (supplier management software).

Set up touchless AP workflows and streamline the Accounts Payable process in seconds. Book a 30-min live demo now.

4. Set up supplier performance evaluation systems

Evaluating supplier performance is essential to maintaining a healthy procurement process. It not only helps identify the best suppliers but also highlights potential areas of risk or improvement.

Guidelines for setting up a supplier performance evaluation system:

- Identify the KPIs that are relevant to your business. These can include delivery time, quality of goods or services, and adherence to contract terms.

- Create a standardized evaluation form that includes these KPIs. This form should be easy to understand and use.

- Train your staff on how to use the evaluation form and what each KPI means. This ensures consistency in how evaluations are conducted.

- Regularly review supplier performance and provide feedback. This can help suppliers improve and align their operations more closely with your needs.

- If a supplier consistently underperforms, consider whether it might be time to find a new supplier. This can be a difficult decision, but it's crucial to maintaining the integrity and efficiency of your procurement process.

5. Implement ethical procurement practices

Ethical procurement practices ensure your business operations align with your core values and social responsibility commitments. This involves considering environmental sustainability, labor rights, and fair trade practices in procurement decisions.

Steps to implement ethical procurement practices:

- Develop a procurement policy that outlines your commitment to ethical practices. This could include policies on environmental sustainability, labor rights, fair trade, and anti-corruption.

- Train your procurement team on this policy and the importance of ethical procurement. This ensures they understand and can effectively implement the policy in their daily work.

- Use supplier screening tools to verify that your suppliers adhere to these ethical practices. These tools can help identify potential red flags and ensure that your suppliers align with your ethical standards.

- Regularly review and update your ethical procurement policy to reflect changes in laws, industry standards, and your company's values.

- Engage in open dialogue with your suppliers about your ethical standards and expectations. This promotes transparency and ensures that your suppliers are aware of and can meet your requirements.

- Consider third-party audits or certifications to validate your ethical procurement practices. This can provide additional assurance to both your company and stakeholders that you are committed to ethical practices.

6. Implement technology to streamline procurement operations

AI, automation, OCR (Optical Character Recognition), and other advanced technologies can streamline procurement operations, reducing costs, enhancing efficiency, and minimizing errors.

Tasks where technology can be implemented:

- Automating purchase orders and invoice processing. This reduces manual intervention, thereby minimizing errors and saving time.

- Using AI for predictive analysis. It can help forecast future procurement needs based on historical data, leading to better planning and inventory control.

- Implementing OCR for document management. It digitally transforms paper documents into editable and searchable data, improving data accessibility and reducing the need for physical storage.

- Using machine learning algorithms for supplier risk assessment. It can help identify potential risks and anomalies more accurately, enabling proactive risk management.

- Integrating a centralized database system. It ensures all procurement-related information is stored in one place, enhancing visibility and internal controls over AP activities.

7. Leverage strategic sourcing

Strategic sourcing is a systematic and fact-based approach for optimizing an organization's supply base and improving the overall value proposition. It involves analyzing the company's spending patterns, understanding the supply market, evaluating suppliers, and developing a long-term procurement strategy.

Questions to ask when leveraging strategic sourcing:

- What are the company's current spending patterns, and where are the opportunities for savings?

- What is the competitive landscape of the supplier market for the goods or services needed?

- How do potential suppliers compare price, quality, delivery reliability, and service?

- What is the risk profile of potential suppliers, and what risk mitigation strategies can be implemented?

- What long-term strategies can be developed to optimize the supply base and enhance the value proposition?

Implementing a strategic sourcing approach can lead to significant cost savings, improved supplier relationships, reduced risks, and increased competitive advantage.

How to create a procurement management plan

Management is incomplete without a well-structured plan. In procurement management, a plan guides the organization's purchasing activities and outlines how procurement tasks will be handled.

Here are the steps to create a robust procurement management plan:

- Start by defining your procurement objectives. These could be reducing costs, improving supplier relationships, ensuring on-time delivery, or enhancing the quality of goods or services.

- Identify the key stakeholders involved in the procurement process. This could include your procurement team, suppliers, and other internal departments that rely on procurement.

- Outline the procurement procedures, from identifying needs to receiving goods or services. This should also include the process for invoice approval and payment.

- Define the roles and responsibilities of everyone involved in the procurement process. This ensures everyone knows what they are expected to do and enables accountability.

- Develop a risk management plan. Identify potential risks in your procurement process and outline strategies to mitigate these risks - Decide on the criteria for selecting and evaluating suppliers. This could be based on price, quality, delivery time, or other significant factors.

- Determine the procurement budget. This should include the cost of goods or services and any additional costs like delivery or import fees.

- Set up a process for handling disputes or issues with suppliers. This could involve a dispute resolution clause in your contracts or a dedicated team to address supplier issues.

- Implement a system for documenting and tracking all procurement activities. This could be procurement software or a simple spreadsheet. The goal is to maintain transparency and accountability in your procurement operations.

- Regularly review and update the procurement management plan as needed. This ensures that the plan stays relevant and effectively meets your procurement objectives.

Automating procurement management

Given the importance of procurement management in the operations of any business, automation is not an option; it's a strategic imperative. A report from Verified Market Research forecasts that the global procurement software market will reach $9.5 billion worldwide by 2028.

Here are the essential aspects that procurement teams can digitize to transform their procurement management activities, improving efficiency, control, and collaboration across the board.

- Automated processes and paperless approvals: Utilizing advanced purchasing systems automates existing procurement activities, enabling paperless approvals and digital authorization. Real-time communication with vendors within these systems resolves issues swiftly, ensuring seamless process flow.

- Vendor management solutions: Digital procurement solutions centralize vendor interactions, simplifying screening, supplier onboarding, performance monitoring, and issue resolution. Everything related to suppliers is managed on a unified digital platform, fostering efficient collaboration and reducing complexities.

- Financial control and reporting: Say goodbye to cumbersome spreadsheets. Online procurement management systems offer precise budgetary control. Users can monitor expenditures, set limits, and access comprehensive reports for strategic insights. Online catalogs maintain accuracy, reducing employee workload and ensuring consistency.

- Robust compliance and confidence: Procurement software compiles vital data in intuitive dashboards, providing a 360-degree view of purchasing performance. This includes adherence to deadlines, quality standards, and compliance with policies, regulations, and legal requirements. Transparent reporting reduces the risks of off-contract purchasing and fraudulent activities, instilling confidence in sourcing processes.

- Insightful reporting and evaluation: Procurement management software offers in-depth data analysis, allowing businesses to assess vendor performance, identify risks, and pinpoint areas for improvement. It empowers informed decision-making and enhances strategic planning.

Selecting the right procurement management software is crucial. Look for features like sophisticated vendor management, customizable workflows, and paperless automation. Robust reporting capabilities ensure comprehensive analysis, enabling compliance enforcement and strategic budgetary control.

Digital procurement isn't merely about automation but efficiency, compliance, and strategic empowerment. By embracing modern procurement solutions, businesses reduce processing time, minimize errors, and enhance employee focus on value-driven activities. Elevate your procurement processes with technology that streamlines operations and positions your organization for future success.

Book this 30-minute live demo to make this the last time you'll have to manually key in data from invoices or receipts into ERP software.

Final thoughts

Today's leading companies recognize the pivotal role of procurement in process enhancement, cost reduction, and heightened customer satisfaction.

By investing in efficient procurement management strategies and embracing automation, businesses not only lower costs and improve supplier relationships but also pave the way for sustainable growth and competitiveness.

Procurement is no longer just necessary; it's a cornerstone of strategic business success, enabling companies to navigate complex supply chains, optimize cash flow, and ensure sustainable value delivery to the business and its stakeholders.

Procurement management FAQs

What is procurement in management?

Procurement in management refers to the strategic process of identifying, acquiring, and managing the goods and services a business needs to fulfill its operational requirements.

It involves sourcing and purchasing items, vendor management, negotiating contracts, and ensuring the quality and timely delivery of goods or services.

Effective procurement management drives cost efficiency, improves supplier relationships, and contributes to the overall strategic success of an organization.

What is a procurement management example?

Procurement management is acquiring goods and services from external sources to support an organization's operations. It involves evaluating vendors, creating purchase orders, approving invoices, managing contracts and suppliers, inventory and risk management, procurement automation, and planning. Effective procurement management practices help organizations acquire necessary goods and services efficiently and cost-effectively while mitigating risks.

What are the seven stages of procurement?

The seven stages of procurement are: identifying the need, specifying the requirements, sourcing potential suppliers, negotiating with suppliers, contract awarding, delivery and performance assessment, and contract administration and closure.

What are the four main roles of procurement?

The four main procurement roles are strategic sourcing, supplier management, contract management, and procurement operations. Strategic sourcing involves identifying, evaluating, and selecting suppliers. Supplier management deals with maintaining and improving supplier relationships. Contract management involves negotiating, administering, and reviewing contracts. Procurement operations focus on the process of acquiring goods and services.

What is contract management in procurement?

Contract management in procurement refers to the process of managing contracts with suppliers. It involves negotiating terms and conditions, ensuring compliance with the contract's terms, monitoring the supplier's performance, and addressing any changes or disputes that arise during the contract's lifecycle. Effective contract management contributes to successful supplier relationships and ensures that the organization receives the expected value from the contract.

What is category management in procurement?

Category management in procurement is a strategic approach that organizes procurement resources to focus on specific areas of spends. This method classifies goods and services into distinct groups based on their function and market dynamics, enabling a focused approach to procurement that can lead to improved supplier relationships, reduced costs, and enhanced efficiency.

What is procurement and supply chain management?

Procurement and supply chain management are closely linked functions within a business. While procurement involves identifying and acquiring goods and services from suppliers, supply chain management encompasses the broader range of activities involved in taking a product from raw material to final product. This includes procurement but also extends to managing the logistics and operations that move goods from suppliers to customers.

What is a procurement management plan?

A procurement management plan is a document that outlines the procurement strategy and processes for a project or organization.

It details how the organization will identify and acquire the necessary goods and services, includes vendor management procedures, contract negotiation strategies, and risk mitigation plans, and outlines the roles and responsibilities of all involved parties.

This plan serves as a guide for all procurement activities, ensuring alignment with the organization's goals and objectives, promoting efficiency, and mitigating risks associated with procurement.